Pretotyping and Lean: a match made in heaven

The world of innovation is filled with methodologies, frameworks and ideas around best practice. Within these ideas, the main question often boils down to: How can we innovate as quickly, as efficiently and as adaptably as possible? While some teams choose to venture down the road of Scrum, or attempt to follow in the footsteps of Amazon’s methodology, others choose the Lean method (when they all should really be choosing pretotyping, but we’ll get to that later).

The Lean method got its start in a little manufacturing company you’ve probably heard of once or twice: the Ford Motor Company. In an effort to eliminate waste and create efficiencies in every area possible, Henry Ford placed enormous importance on his employees and his company ‘working smarter, not harder’. Following Ford’s success, the Lean method has been and is still used by many companies, predominantly within the manufacturing industry; some descendents of Ford’s include Toyota, Intel and John Deere.

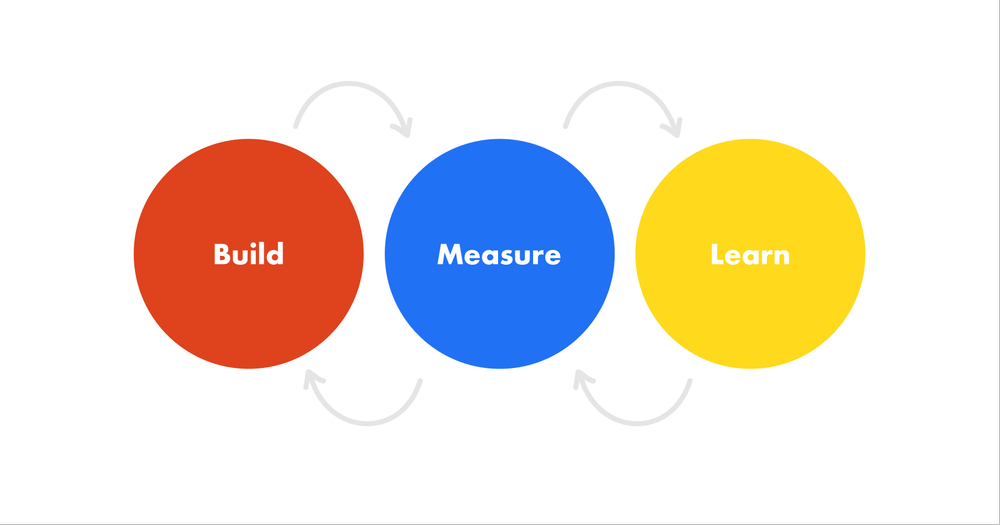

The basic principle of Lean is to make the best possible product, using as little time and resources as possible. Utilising a cyclical process made of three steps - ‘Build, Measure, Learn’ - the Lean method was revolutionary because, according to our founder Leslie Barry, it required teams to “stop postulating and just get out there and build a thing,” measure its success and learn from it going forward. In building the product quickly and efficiently, customer insights are able to be gathered relatively early, with the aim of minimizing even more waste in the product development cycle. This is a method that prioritizes experimentation over a prolonged planning process and celebrates continuous improvement.

Whilst Lean can be a wonderful tool for innovation (as its religiously loyal fans will tell you), it also demonstrates a gap that teams must leap over when choosing it as a strategy: how do we know this idea will even work?

*Enter Pretotyping, stage left!*

Pretotyping, with its rapid experimentation and ‘fail early, fail fast, fail better’ philosophy, neutralises the weaknesses of Lean by reversing the ‘Build, Measure, Learn’ process. By flipping the cycle, pretotyping can then integrate with Lean at both a macro and micro level; it also means that we can know, based on customer data and insights, whether an idea will work. This helps support the Lean process, which tends to start building things based on opinions and guessing - which any pretotyper knows is a terrible idea.

The Pretotyping + Lean method works as a ‘Learn, Measure, Build’ cycle. First, we Learn through pretotyping our way to ideas we know will work, by using rapid experimentation. Next, we Measure the results of those experiments and iterate them to get more data, of a higher and higher quality, then when we have found the idea we know will work, we Build the product and continue iterating, returning back to the Learn part of the cycle. This process still allows for the efficiencies that Lean strives for, but avoids the guessing component that generally causes Lean innovators to build on what they think is a good idea, and what they think their bosses will be willing to fund.

The benefits of adding pretotyping to your lean methodology also helps teams innovate within each stage of the process. “During the initial Learn phase, teams can generate hundreds of ideas,” says Leslie. “With each Lean Canvas and experiment you develop, you learn more about your customers and ideas, and bring this knowledge into your next pretotype, and your next one, and your next one.” The Measure phase helps innovation develop products at a macro level, but it also helps you strengthen your experiments at a micro level, so that you can Build not just better products, but better pretotypes, iterating on your experiments in order to gather more helpful data.

The Pretotyping x Lean method is not only useful for larger organisations like Ford and Toyota, but also for startups; indeed, it’s integral for them, as they are essentially an experiment themselves. Entrepreneur and innovator extraordinaire Eric Ries, in his book The Lean Startup, explains that “startups need to conduct experiments” because the “only way to win is to learn faster than anyone else.” Ries writes that “planning [...] only works in the presence of a long and stable operating history”, citing two key questions when it comes to Lean methods: “which activities create value and which are a form of waste?”. These questions are similarly essential to pretotyping, where rapid experimentation seeks to create value and minimise waste by failing fast and early.

Whilst it’s totally understandable that the thought of introducing a new methodology to the mix can seem like a monumental task, Lean and pretotyping actually work together to make your innovation process easier. Their common celebration of efficiency and their shared mission to create the best possible product (that people will actually use) make them the perfect match.

*

Ready to integrate pretotyping into your innovation process? Contact Leslie to discuss training for your team or company, or sign up for a free preview of our online pretotyping course.